We are experiencing technical difficulties with online orders. We are working to resolve this issue.

-

SEAWEED

SEAWEEDOurstucco Fauxfinish Paint® Seaweed

Excellent Stucco Effect

Simple Construction

3 gal White

$69.9973+ bought in past monthSeaweed Series:

Using natural brown algae powder from the Mediterranean coast and adding environmentally friendly acrylic resin emulsion, it is a high-grade wall material with a slightly yellow seaweed color and imitation stone effect. The VOC content is extremely low, surpassing the environmental protection level of traditional diatom mud paint, anti-formaldehyde, anti-virus, high hardness, moisture-proof and mildew-proof, etc., with simple process, unique pattern, and diverse colors. Simple construction can have a mottled historical stone pattern.

Product components: The main paint components are water, additives, ultra-fine heavy calcium, quartz sand and acrylic resin and other textured paints.

Product features: OURSTUCCO seaweed rock series products have super long slow drying, easy construction, high thixotropy, large-area construction without flower, and clear and natural texture.

Product packaging: Standard packaging of American gallon plastic barrels 5 kg/gallon. 15 kg/10 liters

Product model: The basic models are divided into: ① Fine type ② Standard type ③ 203 large ④ 102 extra large and other series.

Instructions for use: Open the barrel and use. Please close the lid when it is not used up.

Storage instructions: The storage period of seaweed rock series products without opening the lid is 3 years.

Construction instructions: Alkali-resistant primer must be rolled and applied twice. The first time is the base, and the second time is scraped. Let it stand for 10 to 20 minutes. When the surface is more than 80% dry, the washboard S-shaped shape

Coating rate: According to the type and pattern of seaweed rock, the coating rate of fine type is 0.8 to 1.2 square meters; the coating rate of standard type is 0.6 to 0.8 square meters; the coating rate of 203 type is 0.45 to 0.5 square meters; the coating rate of 102 is 0.3 to 0.4 square meters

Glossiness: Seaweed rock series products are generally matte gloss, and can also be sprayed or rolled with bright gloss to make the surface appear eggshell glossy.

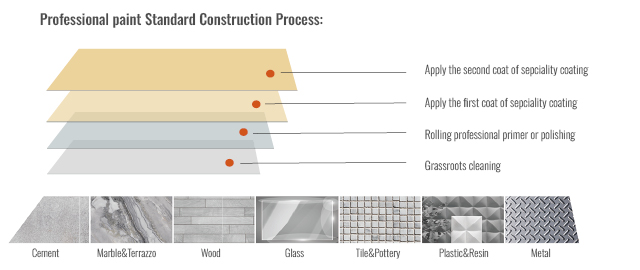

Standard construction process of seaweed rock:

OURSTUCCO seaweed rock has completely surpassed the once popular diatom mud products. It is a real bio-based paint in the art paint industry. It is simple to construct and has unique effects. Its construction requirements and processes are as follows

1. Requirements for wall base:

1. Standard wall: plaster leveling, waterproof putty scraping twice, polishing flat, the flatness must meet the national internal and external wall painting acceptance standards.

2 Different material walls: such as large core board, gypsum board, metal plate, hollow brick and other mixed material handover walls, need to be treated with anti-cracking (such as: full nylon cloth, local anti-cracking mesh cloth, scraping putty, professional anti-cracking mortar, etc.), the treatment process must meet the national internal and external wall painting acceptance standards.

2. Standard construction process of seaweed rock:

1. Rolling primer: Use a short-haired roller to evenly roll the anti-alkali primer once, and the drying time should not be less than 3 hours.

2. Modeling process:

①Use the S-shaped technique of the spatula, with the thickness of one sand grain as the benchmark (it is better to have sand grain scratches locally), and evenly apply the first layer of seaweed rock to prime, and the drying time should not be less than 3 hours.

②Use the S-shaped technique of the metal spatula to apply the second layer of seaweed rock thinly (the thinner the better), and after drying for 5-10 minutes, use a plastic sander or plastic spatula to roughly grind the first layer.

③After the second layer of seaweed rock is dried for 15-30 minutes, finely grind it again to shape it. Different grinding techniques and grinding times can form different patterns.

3. Surface protection: Use a short-haired roller to roll on ordinary interior wall topcoat/semi-matte topcoat/pure matte black hole topcoat one to two times.

Note:

1. Seaweed rock series products have extremely strong slow-drying properties to ensure that there are no scars in the construction of large walls. When making the second layer of modeling of the sample, there must be enough waiting time to get a good rubbing flower.

2. The color of the finished product of the seaweed rock series products is slightly yellowish because they contain seaweed fragments. (Pure white products without seaweed can be customized)

3. When painting the seaweed rock series products on the exterior wall, it is recommended to roll on OURSTUCCO's silicone acrylic varnish.

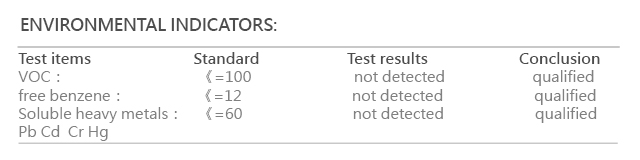

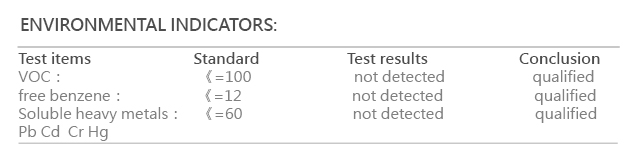

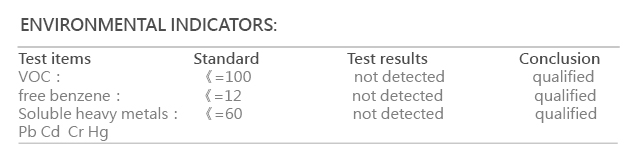

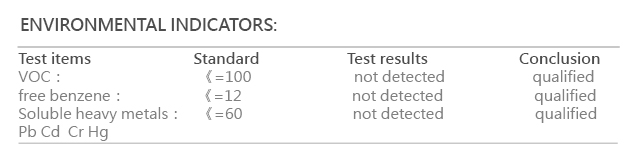

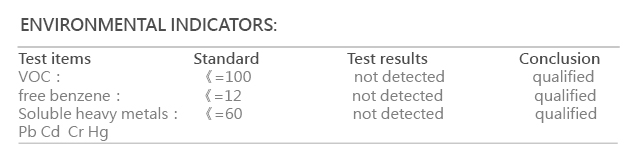

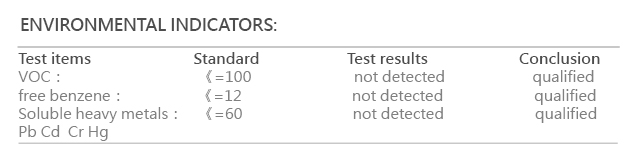

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

Limited Lifetime Warranty:

If this paint does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, provide you with an equal amount of new paint or refund the purchase price of this paint. This warranty does not cover: 1.the labor and labor costs of applying or removing any paint; 2.any incidental or consequential damages, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

To request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

-

MAMORINO

MAMORINOOurstucco Fauxfinish Paint® Mamorino

Excellent Plaster Effect

Smooth with Spatula

3 gal White

$74.9923+ bought in past monthMARMO (Mamorino) Series:

Using high-quality limestone from the mountains on the east coast of Sicily, Italy, and mixed with inorganic silicates, it is an environmentally friendly wall material. The VOC content is extremely low, and the environmental protection level exceeds that of most traditional coatings. It has an ultra-long service life equal to the life of the building. High fire resistance, moisture and mildew resistance, high hardness, good color paste adaptability, colorful, durable and non-fading. It has the unique performance of drying the bottom layer first and drying the surface layer later, and simple construction can present the special pattern and luster of bright plaster.

Product components: The main paint components are water, additives, silicates, fine limestone powder and acrylic resin, etc.

Product features: OURSTUCCO Mamorino series products have the material characteristics of drying the bottom layer first and drying the surface layer later. During construction, they have good polishing construction properties. Simply scrape and polish directly with a spatula when it is 80% dry. Pay attention to the polishing time. Polishing too early will not be easy to polish. Polishing too late will easily produce spatula ash marks.

Product packaging: Standard packaging of American gallon plastic barrels 5 kg/gallon or 15 kg/10 liters

Product model: The product is ① Mamo (Mamorino glossy fine type) ② Mamorui (Mamorino silky standard type)

Instructions for use: Open the barrel and stir before use. Please close the barrel cover when it is not used up.

Storage instructions: The unopened storage period of Mamorino series products is 3 years.

Construction instructions: The wall surface must be flat and roll on the alkali-resistant primer; according to the artistic effect required by the customer, choose different construction tools and construction techniques for fast construction. The surface must be sprayed with glazing or scraped with Italian water wax products to ensure the waterproofness of the surface.

Coating rate: The different models of Mamorino series products have a coating rate of 0.8~1.5 square meters/kg.

Gloss: Mamorino series products are generally silky luster when they are well polished or polished. After scraping Italian water wax or spraying silicone acrylate glazing, the luster will become oily.

Product maintenance: Apply various high-performance topcoats. It will extend the service life of Mamorino products. When the Mamorino product series is used outdoors, exterior wall color paste must be used to improve durability and UV resistance.

Process flow of glossy Marmo:

OURSTUCCO's glossy Marmo has surpassed similar products from domestic and foreign manufacturers. It is a classic product of sand-containing glossy plaster in the art paint industry. It is simple to construct and has unique effects. Its construction requirements and basic processes are as follows:

1. Requirements for wall base:

1. Standard wall: plaster leveling, waterproof putty scraping twice, polishing flat, and the flatness meets the national internal and external wall painting acceptance standards.

2. Walls of different materials: such as large core board, gypsum board, metal plate material, hollow brick and other mixed material intersection walls, need to be treated with anti-cracking, such as: full nylon cloth, local anti-cracking mesh cloth, scraping putty, professional anti-cracking mortar, etc. The processing process must meet the national internal and external wall painting acceptance standards.

2. Standard construction process of glossy Marmo:

1. Use a short-haired roller to evenly roll the anti-alkali primer once, and the drying time should not be less than 3 hours.

2. Use the spatula S-shaped technique to evenly apply the first coat of glossy Marmo as a primer and dry it for 2 hours.

3. Use the spatula S-shaped technique to evenly apply the second coat of glossy Marmo and dry it for 4 hours.

4. Use 240~320 mesh sandpaper for simple rough grinding, and then use 600 mesh sandpaper or sanding disc to polish directly.

5. Use a spatula to apply Italian water wax once or roll it to cover it.

Note:

1. The glossy Marmo series can also DIY the mottled effect. Process step 3: Use the spatula S-shaped technique to normally apply the second coat of glossy Marmo. After drying for 3~5 minutes, you can refer to the European colored jade finishing process to produce a mottled and staggered mottled effect.

2. For the Mamorino series products (standard Marmo series), master the appropriate finishing and calendering time, and you can use a spatula to directly finish it to produce an eggshell light effect.

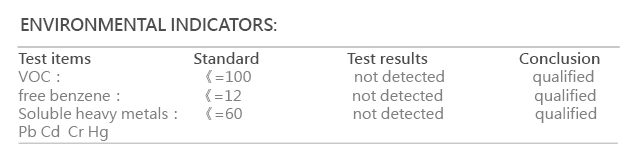

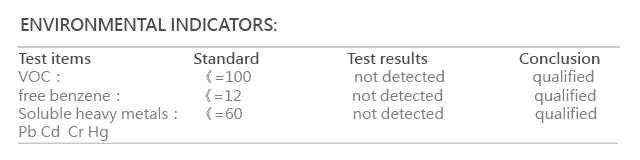

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

Limited Lifetime Warranty:

If this paint does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, provide you with an equal amount of new paint or refund the purchase price of this paint. This warranty does not cover: 1.the labor and labor costs of applying or removing any paint; 2.any incidental or consequential damages, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

TTo request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

-

MICROCEMENT

MICROCEMENTOurstucco Fauxfinish Paint® Microcement

Lustrous Cement Effect

Construct with Spatula

3 gal White

$69.9935+ bought in past monthMicrocement:

The wall environmental protection material with macromolecular polymer resin and high-purity silica as the main raw materials surpasses the texture and texture of traditional two-component microcement, providing pure colors with higher saturation and richer hue selection. The construction is simpler and it is not easy to produce mottled joints. The microcrystal series is a stable paste finished material. There is no need to mix multiple components. The coloring and construction are completed in one go.

Product components: The main paint components are water, additives, quartz sand, fine heavy calcium and acrylic resin, etc.

Product features: OURSTUCCO paste microcement series products have good modeling construction, excellent color matching, and stable color. Simply scraping can make the wall effect of microcement, and the process can also be changed to make a series of textured texture shapes.

Product packaging: Standard packaging of American gallon plastic barrels 15 kg/10 liters

Product model: The product is a paste fine plaster

Instructions for use: Use it as soon as the barrel is opened. Please close the barrel lid when it is not used up.

Storage instructions: The unopened storage period of the paste microcement series products is 3 years.

Construction instructions: The wall surface must be flat, roll on the alkali-resistant primer; according to the color required by the customer, use a spatula to quickly scrape and apply two coats. The first coat is used as a primer, and the second coat can be partially flattened as a surface layer. It is recommended to roll on the second generation of black hole varnish. In the bathroom and kitchen light area, it is recommended to roll on the two-component varnish to achieve better stain resistance and scratch resistance.

Coating rate: The approximate coating rate of the paste microcement series is 2 square meters/kilogram.

Gloss: The paste microcement series products are generally matte textured, and the black hole varnish is basically pure matte. Rolling or spraying silicone acrylic or two-component varnish will have a certain oily gloss.

Product maintenance: In order to ensure the firmness and later service life of the product, other types of high-performance topcoats can be applied. When the paste microcement product series is applied outdoors, exterior wall color paste must be used to improve durability and UV resistance.

Standard construction process of wall microcement:

OURSTUCCO wall microcement (paste microcement) uses high-hardness silica and high-glass transition temperature emulsion from BASF, Germany. It is a new wall decoration imitation cement paint with high hardness, good stain resistance, mildew resistance, moisture resistance, uniform color, high saturation, etc. Its construction requirements and processes are as follows:

1. Wall base requirements:

1. Standard wall: plaster leveling, waterproof putty scraping twice, polishing flat, the flatness must meet the national internal and external wall painting acceptance standards.

2 Different material walls: such as large core board, gypsum board, metal plate, hollow brick and other mixed material handover wall, need to do anti-cracking treatment (such as: full nylon cloth, local anti-cracking mesh cloth, scraping putty, professional anti-cracking mortar, etc.), the treatment process must meet the national internal and external wall painting acceptance standards.

2. Paste microcement construction process:

1. Roll primer: Use a short-haired roller to evenly roll the anti-alkali primer once, and the drying time is not less than 3 hours.

2. Modeling process:

① Use a spatula in an S-shaped manner, with the thickness of one sand grain as the benchmark (it is better to have sand grain scratches locally), and evenly apply the first coat of paste-like microcement as the base, and the drying time should be no less than 3 hours.

② Use a metal spatula in an S-shaped manner, and apply the second coat of wall microcement thinly. After drying for a few minutes, find the time point for leveling and use a spatula to level it directly.

3. Surface protection: Use a short-haired roller to roll on ordinary interior wall topcoat/semi-matte topcoat/pure matte black hole topcoat one to two times. Notes:

(1) Sanding: The wall microcement can be lightly sanded with sandpaper, and the sandpaper marks can be removed after rolling on the topcoat.

(2) Color calibration: The color adjustment coefficient of wall microcement is different from that of two-component microcement. Please carefully calibrate the color before applying them separately.

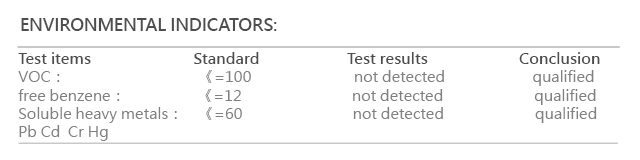

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

Limited Lifetime Warranty:

If this paint does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, provide you with an equal amount of new paint or refund the purchase price of this paint. This warranty does not cover: 1.the labor and labor costs of applying or removing any paint; 2.any incidental or consequential damages, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

To request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

-

LEATHER

LEATHEROurstucco Fauxfinish Paint®Leather

Classic Leather Effect

Component A & Component B

1 gal Base

$169.999+ bought in past monthLeather Series:

A new series of products in the coating industry, using natural white marble and quartz powder, and environmentally friendly imitation leather materials made with polymer resin. It has the same texture and feel as genuine leather. It is a top-level wall material with extremely low VOC content, surpassing the environmental protection level of traditional coatings, anti-electromagnetic, anti-radiation, moisture-proof and mildew-proof, and high fire resistance. It is a pure inorganic material with bright colors and durable and non-fading. Simply roll or spray to get a special leather pattern effect

Product components: The main paint components are water, additives, mica powder, fine heavy calcium and acrylic resin, etc.

Product features: OURSTUCCO imitation leather series products have a special leather luster and pattern that can be obtained by simply rolling, and have a simulation effect of almost 90% of leather.

Product packaging: Standard packaging of American gallon plastic barrels 5 kg/gallon.

Product model: The product is ① leather midcoat A ② leather topcoat ③ leather topcoat, three basic products.

Instructions for use: Use after opening the barrel. Please close the barrel lid when it is not used up.

Storage instructions: The unopened storage period of the imitation leather series products is 3 years.

Construction instructions: Must roll on the alkali-resistant primer, roll on the colored primer once, and after drying, roll on one or two times of ① leather intermediate coating. After completely drying, roll on ② leather topcoat two to three times. The first coat of leather topcoat must be rolled thinly. Finally, it is necessary to roll on appropriate finishing paint.

Coating rate: The coating rate of the imitation leather intermediate coating is 2.5~3.3 square meters/kg; the coating rate of the topcoat is 2.5~4 square meters/kg.

Gloss: The imitation leather series products are generally matte gloss. According to the roughness of the substrate, the surface can also present an eggshell gloss. Ourstucco's professional leather PU topcoat can obtain a matte or glossy leather effect.

Product maintenance: In order to ensure the firmness and later service life of the product, you can apply other types of finishing paints. Applying finishing paints may reduce the feel of the leather paint and change the original gloss.

Standard construction process of leather paint:

The leather series launched by OURSTUCCO is a brand-new product in the entire art paint industry. Through simple rolling, you can achieve the texture and feel of genuine leather. Its construction requirements and processes are as follows:

A. Wall base requirements:

1. Standard wall: plaster leveling, waterproof putty scraping twice, polishing flat, the flatness must meet the national internal and external wall painter acceptance standards.

2. Walls of different materials: such as large core board, gypsum board, metal plate, hollow brick and other mixed material intersection walls, need to be treated with anti-cracking (such as: full nylon cloth, partial anti-cracking mesh cloth, scraping putty, professional anti-cracking mortar, etc.), the treatment process must meet the national internal and external wall painter acceptance standards.

B. Basic products:

· Anti-alkali primer · Color primer · Leather midcoat · Leather topcoat · Two-component leather cover

C. Standard construction process of leather paint:

1. Use a short-haired roller to evenly roll the anti-alkali primer once, and the drying time is not less than 3 hours.

2. Roll on leather primer (the color of the leather grain is exposed. It is generally recommended to choose a dark color, but it can also be adjusted according to customer requirements)

3. Use a short-haired roller with a medium thickness to roll on the leather mid-coat one to two times (each time it takes 6 hours to dry)

4. Use a fine sponge roller to roll on the leather topcoat two to three times.

The first time should be rolled as thin as possible. After drying for 2 to 3 hours, you can see very small cracks.

The second time should be rolled with a medium thickness. After drying for 2 to 3 hours, you can get a stable and uniform leather texture.

(You can also roll on the third time. The more times you roll, the rougher the leather texture will be)

5. Roll on a two-component 360 varnish or a professional leather PU varnish.

Notes:

(1) The thickness of the leather mid-coat determines the size of the cracks in the leather.

(2) For the first time of leather topcoat, the finer the cracks, the easier it is to control the overall leather effect.

(3) The leather topcoat can be rolled on multiple times. The texture ranges from fine to rough. The number of times can be determined according to customer requirements.

(4) All colors of leather primer and topcoat are supported by the color system and are all computer-adjusted.

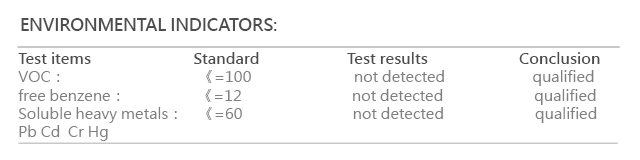

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

Limited Lifetime Warranty:

If this paint does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, provide you with an equal amount of new paint or refund the purchase price of this paint. This warranty does not cover: 1.the labor and labor costs of applying or removing any paint; 2.any incidental or consequential damages, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

To request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

-

TRAVERTINUS

TRAVERTINUSOurstucco Fauxfinish Paint® Travertinus

Excellent Plaster Effect

Construct with Spatula

3 gal White

$74.994+ bought in past monthTravertinus Series:

An environmentally friendly material made of high-quality limestone mixed with inorganic silicate from the east coast mountains of Sicily, Italy. It is an ultra-long service life wall material with the same lifespan as the building. It has extremely low VOC content, surpasses the environmental protection grade of traditional coatings, has high fire resistance, is moisture-proof and mildew-proof, and has high hardness. The fifth generation neutral silicate material has bright colors and is durable and does not fade. At the same time, it has the special construction performance of drying the bottom layer first and then drying the surface layer. With simple construction, the special pattern of silicate paint can be obtained, and the effect is remarkable.

Product components: The main paint ingredients are water, additives, silicates, limestone powder and acrylic resin.

Product features: OURSTUCCO Travertinus series products have good modeling and construction properties. Simply scrape and scrape with the tip of a spatula to create a series of textured shapes. The special feature of drying the bottom layer first and then the top layer also facilitates smoothing and calendering after styling.

Product packaging: standard packaging in American gallon plastic barrels 5 kg/gallon or 15 kg/10 liters

Product model: The product is ① fine type ② standard type ③ 203 castle stone ④ 102 Roman travertine ⑤ volcanic rock series ⑥ coral stone series ⑦ mottled plaster ⑧ colored fair concrete ⑨ efflorescence fair concrete ⑩ pottery colored stone

Instructions for use: Ready to use. When not in use, please close the lid.

Storage instructions: The storage period of Travertinus series products without opening the lid is 3 years.

Construction instructions: The wall surface must be smooth, and the anti-alkali primer should be rolled on. According to the artistic effect required by the customer, different construction tools and construction techniques should be selected for rapid construction. The surface must be spray-coated or scraped with Italian water wax products to ensure the surface is waterproof.

Coating rate: The approximate coating rate of different models of Travertinus series products is 0.25~0.8 square meters/kg.

Glossiness: Travertinus series products are generally matte in texture. After scraping Italian water wax or spraying silicone acrylic to cover the surface, there will be a certain oily gloss.

Product maintenance: In order to ensure the firmness of the product and its later service life, other types of high-performance topcoats can be applied. When applying the Travertinus product range outdoors, exterior wall colorants must be used to improve durability and UV resistance.

Travertinus standard process flow:

OURSTUCCO's Travertinus has surpassed similar products of Italian manufacturers in all aspects. It is a classic modeling plaster paint in the art paint industry. It is easy to apply and has unique effects. Its construction requirements and processes are as follows:

1. Rolling primer: Use a short-haired roller to evenly roll the anti-alkali primer once, and the drying time should not be less than 3 hours.

2. Modeling process:

① Use the S-shaped technique of the spatula, with a sand grain thickness as the benchmark (local sand grain scratches are preferred), and evenly apply the first coat of Travertinus for priming, and dry for 3 to 5 hours.

② Use a metal spatula to evenly apply the second coat of Travertinus. After drying for 5 to 10 minutes, you can use the spatula tip to scrape and lightly sweep the sand surface to create a classic bark; you can also use the spatula S-shaped sweeping operation to create messy lines or fishtail lines.

③ After 5 to 15 minutes of modeling the second coat of Travertinus, you can use a spatula to level it.

3. Surface protection: Use a spatula to apply Italian water wax, or use a short-haired roller to apply ordinary interior wall topcoat/semi-matte topcoat/pure matte black hole topcoat.

Notes:

(1) The classic performance of plaster, it can be directly flattened while shaping, and it feels great (no sandpaper is needed).

(2) It is recommended to apply Italian water wax on the surface of plaster products, which can improve performance and produce more natural patterns.

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

Limited Lifetime Warranty:

If this paint does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, provide you with an equal amount of new paint or refund the purchase price of this paint. This warranty does not cover: 1.the labor and labor costs of applying or removing any paint; 2.any incidental or consequential damages, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

To request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

-

VELVET

VELVETOurstucco Fauxfinish Paint®Velvet

Classic pearlescent velvet effect

Polished with plastic spatula

1 gal Silver

$119.9922+ bought in past monthVersailles Velvet:

Using Germany's top Merck pearlescent pigments and Germany's BASF acrylic emulsion, environmentally friendly pearlescent materials, edible mica and titanium dioxide coating technology, the metallic luster is natural and soft, with a variety of varieties, simple process, textured shape, unique pattern and extremely low VOC content, surpassing the environmental protection level of most traditional water-based coatings. High fire resistance, moisture and mildew resistance, high hardness, bright colors, high saturation, strong UV resistance, durable and non-fading, long-lasting mottled metal texture with a long history, and has the unique elegance of the royal family.

Product components: The main paint components are water, additives, mica powder, pearl powder and acrylic resin, etc.

Product features: OURSTUCCO velvet series products have stable coatings, high adhesion, special luster and patterns, simple construction technology, and show classic pearlescent color kneading effects.

Product packaging: Standard packaging of American gallon plastic barrels 5 kg/gallon

Product model: The basic models are divided into: ① Versailles velvet (semi-matte) A ② Transparent velvet (light color without graying) ③ Italian satin velvet ④ Glossy velvet 83 type (flash) ⑤ High gloss velvet (high flash) ⑥ Alsa velvet (semi-matte feel) ⑦ Redon velvet ⑧ 102 gold velvet (gold foil type) ⑨ 130 copper velvet (copper foil type) ⑩ 122 red copper velvet (red copper foil), etc., a total of more than 20 models of velvet series, the products cover 90% of similar Italian product models on the market.

Instructions for use: Use after opening the bucket. Please close the lid when it is not used up.

Storage instructions: The storage period of velvet series products without opening the lid is 3 years.

Construction instructions: Alkali-resistant primer must be rolled on. After drying, roll on the same color primer once, roll on velvet two to three times, and use an oblique brush, a multi-purpose brush, a stainless steel spatula, etc. to sweep or scrape.

Coating rate: The coating rate of velvet is 8~15 square meters/kg. Generally speaking: the coating rate of batch coating process is low, and the brush coating process can generally reach a high coating rate of more than 10 square meters.

Glossiness: Velvet series products generally have a bright gloss. Depending on the roughness of the substrate, the surface can also be reflected as a mottled eggshell gloss. Use OURSTUCCO's professional velvet sand primer as the base and Versailles velvet series as the surface layer to obtain a velvet effect close to matte.

Product maintenance: In order to ensure the firmness and later service life of the product, you can apply a topcoat, but applying a topcoat will reduce the feel of the velvet and change the original gloss.

Velvet product base construction process:

1. Use a short-haired roller to evenly roll the anti-alkali primer once, and the drying time should not be less than 3 hours.

2. Same color primer: For some products, it is recommended to roll the same color primer with a short-haired roller.

3. [Polishing velvet] General construction process:

A. Use a short-haired roller, S-shaped roller to polish velvet products for the first time, and apply the primer.

B. Rough polishing: Use a short-haired roller, S-shaped roller corresponding to the second time of velvet products, use a plastic polygonal plastic spatula or plastic sander, S-shaped random pattern, and rough polishing once.

C. Fine polishing: Use a short-haired roller, S-shaped roller corresponding to the third time of velvet products, use a plastic polygonal plastic spatula or plastic sander, S-shaped random pattern, and fine polishing once.

4. [Modeling velvet] General construction process:

A. Use a short-haired roller, S-shaped roller to apply the first time of modeling velvet products, and apply the primer.

B. Primary modeling: Use a short-haired roller to roll the velvet product in an S-shaped roller for the second time. You can also use seaweed cotton rollers, multi-purpose sweepers, plastic spatulas, brown brushes, deerskin dippers, wool dippers, etc. to perform modeling operations.

C. Secondary modeling: According to the effect requirements, secondary modeling operations can be performed, and the tools and processes are the same as above.

5. Remarks:

Some velvet products can be rolled and coated according to customer effect and performance requirements. Use a short-haired roller to roll ordinary interior wall topcoat, semi-matte topcoat, pure matte black hole topcoat, or two-component topcoat. It can improve the stain resistance, scratch resistance and other properties, and extend the service life of velvet products.

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

Limited Lifetime Warranty:

If this paint does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, provide you with an equal amount of new paint or refund the purchase price of this paint. This warranty does not cover: 1.the labor and labor costs of applying or removing any paint; 2.any incidental or consequential damages, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

To request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

-

GLASS PAINT

GLASS PAINTOurstucco® Professional Glass Paint

Supported by color dispenser

Spraying, Exterior Interior

1 gal, Transparent

$194.999+ bought in past monthGlass Paint :

OURSTUCCO's glass color-changing paint, which is divided into two types, transparent and frosted, is a subversive product that changes the color and resists scratches on glass or acrylic. Normally used glass color-changing paint has high adhesion and strong scratch resistance. It provides designers with a wide range of application possibilities in glass decoration in various offices, restaurants, entertainment venues, etc., making glass no longer limited to the traditional dull image, but become a part of space design.

Description:

OURSTUCCO glass color-changing paint, is a two-component polyurethane paint with high adhesion, high hardness, scratch resistance and waterproofness. It is divided into three types: mercerized, eggshell and matte. It has rich colors and supports computer color matching. For roller coating construction, it is recommended to use high-performance curing agent first

Composition:

The main paint components are water, quartz sand, additives and polyurethane silicone modified coatings. Component B is a nano-associative agent. The best paint film performance is achieved after 7 days of mixing A and B. The performance exceeds most international water-based industrial paint standards.

Performance:

High hardness: provide high -hardness and excellent resistance.

High flexibility:Has high flexibility, and tensile stretching performance.

High adhesion: It has a strong adhesion, suitable for various materials such as ceramics, metals, wood, glass,JRC resin and other materials.

Strong waterproofing: superior waterproof performance, suitable for humid environment and soaking places in all year round.

Strong alkaline: suitable for strong alkaline materials such as cement floor.

Color persistence:protect the stability of color pulp, make color saturation and durability higher.

Time tolerance: persistent weather resistance, 10 years of outdoor project warranty (non -artificial damage).

Fire fire level: in water -based coatings, the fire level is very high(Except for professional fireproof coatings).

Antibacteriality:anti -mildew, anti -bacterial, providing additional dry membrane anti -mold guarantee.

High temperature resistance: under the condition of boiling water, keep the painting of the paint the basic performance unchanged.

Color Grading Index:

The main paint of component A can be tinted and is divided into three chromaticity base paints: light base L, medium base M and dark base D. The color code of the color-changing paint is: OST-XX-0000X. The first letter X in the middle represents the color-changing series, the second X represents the glossiness (L represents gloss, Y represents matte), the following 4 digits represent the color-changing number, and the last letter X represents the type of color-changing base paint (L represents light base, M represents medium base). When using, after the A base paint is tinted, add the nano-associative agent of component B, mix well, and then it can be used. The standard mixing ratio of component A and component B is 7:1.

Do not use A and B for more than 3 hours after mixing.

For coloring, please use internationally renowned water-based environmentally friendly colorants or OURSTUCCO American-made colorants. You can ask the company for professional color cards and coloring data sheets, and do manual DIY coloring. The company provides gold-medal agents with DATACOLOR color picking system and fully automatic computer coloring system. After formal training, they can experience color and provide services.

Color card color code for professional color-changing paint: Adopting the 1011 color coding system of artistic paint, taking into account two major types of agents who use manual color matching and fully automatic computer color matching, providing conventional light base (L) and medium base (M) color matching. For darker colors, please use dark base (D) color matching, please consult the American OURSTUCCO company for details.

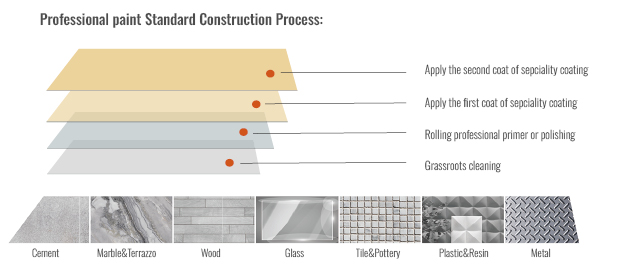

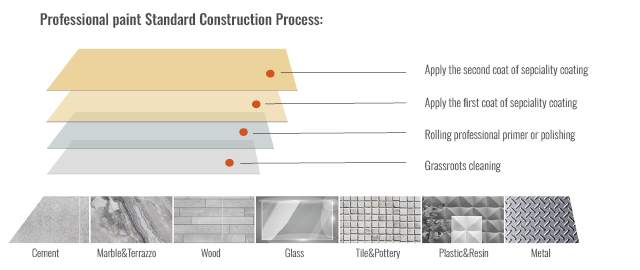

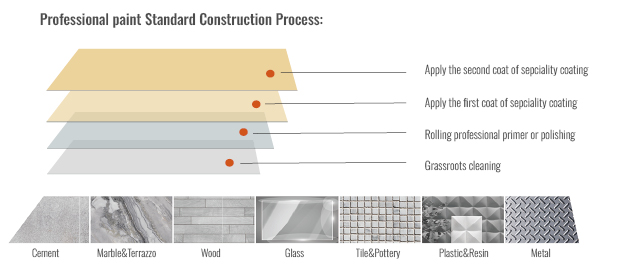

Standard Construction Process:

1. Clean up grass -roots materials: Clean the surface of (including glass, ceramics, metals, wood, stone, GRC Resin, cement floor, epoxy floor, etc.) and dry them.

2. Mixed AB component: Mix the specific coatings A component A and the B component at 6: 1, and mix it evenly. (After mixing A and B, it is recommended to use it within 3 hours)

3. Apply brush for the first time (dry 6 hours or more)

4 .Pick up the second time (you can use it slightly after 24 hours, and reach the best performance after 7 days)

Supplementary description:

Aluminum gusset color change coating: need to apply aluminum substrate professional primer

Cement floor and self -flowing: need to paint the professional primer of cement.

Technical Data:

Coverage: Indoor speciality coatings. Approximately 1 litre per 5~8 square meters on smooth surface; speciality coatings for exterior use approximately 1 liter per 4.5~7square meters; Glass paint approximately 1 liter per 10~15 square meters; Metal paint approximately 1 liter per 5~8 square meters; Ceramic coatings approximately 1 liter per 5~8 square meters; Wood paint approximately 1 liter per 4.5~8 square meters; Cement floor coatings approximately 1 liter per 4~8 square meters.

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

LIMITED LIFETIME WARRANTY:If this coating does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, either provide you with an equal amount of new coating or refund the purchase price of this coating. This warranty does not cover any claims, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

To request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

POPULAR COLORS -

EBONITE PAINT

EBONITE PAINTOurstucco® Professional Ebonite Paint

Supported by color dispenser

Flat, Floor Exterior Interior

1 gal, White

$189.993+ bought in past monthEbonite Paint(Floor covering) :

Ebonite (hard rubber) is a commonly used environmentally friendly decorative material without excessive consideration and grassroots treatment. Widely used in hospitals, kindergartens, schools, and various office spaces. However, due to the limitation of Ebonite production technology, it is difficult to achieve the color and style of space. In order to solve this problem, the United States OURSTUCCO focuses on navigation guidance changes in education, medical and office places, and launched professional Ebonite(hard rubber) color coating. It is widely used in the fields of hospital changes, school changes in schools, color changes in kindergartens, and office space changes.

Description:

OURSTUCCO ebonite floor color coatings is a two-component polyurethane paint with high adhesion, high hardness, scratch resistance and waterproofness. It is divided into three types: mercerized, eggshell and matte. It has rich colors and supports computer color matching. For roller coating construction, it is recommended to use high-performance curing agent first

Composition:

The main paint components are water, quartz sand, additives and polyurethane silicone modified coatings. Component B is a nano-associative agent. The best paint film performance is achieved after 7 days of mixing A and B. The performance exceeds most international water-based industrial paint standards.

Performance:

High hardness: provide high -hardness and excellent resistance.

High flexibility:Has high flexibility, and tensile stretching performance.

High adhesion: It has a strong adhesion, suitable for various materials such as ceramics, metals, wood, glass,JRC resin and other materials.

Strong waterproofing: superior waterproof performance, suitable for humid environment and soaking places in all year round.

Strong alkaline: suitable for strong alkaline materials such as cement floor.

Color persistence:protect the stability of color pulp, make color saturation and durability higher.

Time tolerance: persistent weather resistance, 10 years of outdoor project warranty (non -artificial damage).

Fire fire level: in water -based coatings, the fire level is very high(Except for professional fireproof coatings).

Antibacteriality:anti -mildew, anti -bacterial, providing additional dry membrane anti -mold guarantee.

High temperature resistance: under the condition of boiling water, keep the painting of the paint the basic performance unchanged.

Color Grading Index:

The main paint of component A can be tinted and is divided into three chromaticity base paints: light base L, medium base M and dark base D. The color code of the color-changing paint is: OST-XX-0000X. The first letter X in the middle represents the color-changing series, the second X represents the glossiness (L represents gloss, Y represents matte), the following 4 digits represent the color-changing number, and the last letter X represents the type of color-changing base paint (L represents light base, M represents medium base). When using, after the A base paint is tinted, add the nano-associative agent of component B, mix well, and then it can be used. The standard mixing ratio of component A and component B is 7:1.

Do not use A and B for more than 3 hours after mixing.

For coloring, please use internationally renowned water-based environmentally friendly colorants or OURSTUCCO American-made colorants. You can ask the company for professional color cards and coloring data sheets, and do manual DIY coloring. The company provides gold-medal agents with DATACOLOR color picking system and fully automatic computer coloring system. After formal training, they can experience color and provide services.

Color card color code for professional color-changing paint: Adopting the 1011 color coding system of artistic paint, taking into account two major types of agents who use manual color matching and fully automatic computer color matching, providing conventional light base (L) and medium base (M) color matching. For darker colors, please use dark base (D) color matching, please consult the American OURSTUCCO company for details.

Standard Construction Process:

1. Clean up grass -roots materials: Clean the surface of (including glass, ceramics, metals, wood, stone, GRC Resin, cement floor, epoxy floor, etc.) and dry them.

2. Mixed AB component: Mix the specific coatings A component A and the B component at 6: 1, and mix it evenly. (After mixing A and B, it is recommended to use it within 3 hours)

3. Apply brush for the first time (dry 6 hours or more)

4 .Pick up the second time (you can use it slightly after 24 hours, and reach the best performance after 7 days)

Supplementary description:

Aluminum gusset color change coating: need to apply aluminum substrate professional primer

Cement floor and self -flowing: need to paint the professional primer of cement.

Technical Data:

Coverage: Indoor speciality coatings. Approximately 1 litre per 5~8 square meters on smooth surface; speciality coatings for exterior use approximately 1 liter per 4.5~7square meters; Glass paint approximately 1 liter per 10~15 square meters; Metal paint approximately 1 liter per 5~8 square meters; Ceramic coatings approximately 1 liter per 5~8 square meters; Wood paint approximately 1 liter per 4.5~8 square meters; Cement floor coatings approximately 1 liter per 4~8 square meters.

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

LIMITED LIFETIME WARRANTY:If this coating does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, either provide you with an equal amount of new coating or refund the purchase price of this coating. This warranty does not cover any claims, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

To request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

POPULAR COLORS -

POTTERY PAINT

POTTERY PAINTOurstucco® Professional Pottery Paint

Supported by color dispenser

Flat, Floor Exterior Interior

1 gal, White

$204.997+ bought in past monthPottery Paint :

OURSTUCCO has always been a leader in the field of high temperature resistant ceramic paint. The ceramic paint we bring to you not only maintains excellent performance in boiling water, but also has excellent adhesion, strong stain resistance and waterproof performance. It is widely used in bathtubs, radiators, wash basins, toilets and other places. Its excellent waterproof performance ensures that it remains stable in a humid environment. At the same time, its strong adhesion and stain resistance make it not easy to peel off in long-term use, easier to clean, and maintain the beauty of the facilities.

Description:

OURSTUCCO High -performance pottery coatings is a two-component polyurethane paint with high adhesion, high hardness, scratch resistance and waterproofness. It is divided into three types: mercerized, eggshell and matte. It has rich colors and supports computer color matching. For roller coating construction, it is recommended to use high-performance curing agent first.

Composition:

The main paint components are water, quartz sand, additives and polyurethane silicone modified coatings. Component B is a nano-associative agent. The best paint film performance is achieved after 7 days of mixing A and B. The performance exceeds most international water-based industrial paint standards.

Performance:

High hardness: provide high -hardness and excellent resistance.

High flexibility:Has high flexibility, and tensile stretching performance.

High adhesion: It has a strong adhesion, suitable for various materials such as ceramics, metals, wood, glass,JRC resin and other materials.

Strong waterproofing: superior waterproof performance, suitable for humid environment and soaking places in all year round.

Strong alkaline: suitable for strong alkaline materials such as cement floor.

Color persistence:protect the stability of color pulp, make color saturation and durability higher.

Time tolerance: persistent weather resistance, 10 years of outdoor project warranty (non -artificial damage).

Fire fire level: in water -based coatings, the fire level is very high(Except for professional fireproof coatings).

Antibacteriality:anti -mildew, anti -bacterial, providing additional dry membrane anti -mold guarantee.

High temperature resistance: under the condition of boiling water, keep the painting of the paint the basic performance unchanged.

Color Grading Index:

The main paint of component A can be tinted and is divided into three chromaticity base paints: light base L, medium base M and dark base D. The color code of the color-changing paint is: OST-XX-0000X. The first letter X in the middle represents the color-changing series, the second X represents the glossiness (L represents gloss, Y represents matte), the following 4 digits represent the color-changing number, and the last letter X represents the type of color-changing base paint (L represents light base, M represents medium base). When using, after the A base paint is tinted, add the nano-associative agent of component B, mix well, and then it can be used. The standard mixing ratio of component A and component B is 7:1.

Do not use A and B for more than 3 hours after mixing.

For coloring, please use internationally renowned water-based environmentally friendly colorants or OURSTUCCO American-made colorants. You can ask the company for professional color cards and coloring data sheets, and do manual DIY coloring. The company provides gold-medal agents with DATACOLOR color picking system and fully automatic computer coloring system. After formal training, they can experience color and provide services.

Color card color code for professional color-changing paint: Adopting the 1011 color coding system of artistic paint, taking into account two major types of agents who use manual color matching and fully automatic computer color matching, providing conventional light base (L) and medium base (M) color matching. For darker colors, please use dark base (D) color matching, please consult the American OURSTUCCO company for details.

Standard Construction Process:

1. Clean up grass -roots materials: Clean the surface of (including glass, ceramics, metals, wood, stone, GRC Resin, cement floor, epoxy floor, etc.) and dry them.

2. Mixed AB component: Mix the specific coatings A component A and the B component at 6: 1, and mix it evenly. (After mixing A and B, it is recommended to use it within 3 hours)

3. Apply brush for the first time (dry 6 hours or more)

4 .Pick up the second time (you can use it slightly after 24 hours, and reach the best performance after 7 days)

Supplementary description:

Aluminum gusset color change coating: need to apply aluminum substrate professional primer

Cement floor and self -flowing: need to paint the professional primer of cement.

Technical Data:

Coverage: Indoor speciality coatings. Approximately 1 litre per 5~8 square meters on smooth surface; speciality coatings for exterior use approximately 1 liter per 4.5~7square meters; Glass paint approximately 1 liter per 10~15 square meters; Metal paint approximately 1 liter per 5~8 square meters; Ceramic coatings approximately 1 liter per 5~8 square meters; Wood paint approximately 1 liter per 4.5~8 square meters; Cement floor coatings approximately 1 liter per 4~8 square meters.

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

LIMITED LIFETIME WARRANTY:If this coating does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, either provide you with an equal amount of new coating or refund the purchase price of this coating. This warranty does not cover any claims, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

To request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

POPULAR COLORS -

EPOXY FLOOR

EPOXY FLOOROurstucco® Professional Epoxy Paint

Supported by color dispenser

Flat,Floor,Exterior Interior

1 gal, White

$179.9917+ bought in past monthEpoxy Floor :

The floor of the United States OURSTUCCO has a color change coating, using pure water formula, no solvent volatilization, and high environmental protection index. There is almost no uncomfortable taste during construction. After drying, the hardness can reach more than 5h. Can be used directly. It has the world’s leading abrasion coefficient and scratch resistance, and at the same time has strong waterproofing and weather resistance. It is specialized in the color modification and performance improvement of outdoor cement floor and indoor epoxy floor.

Description:

OURSTUCCO cement floor color coatings is a two-component polyurethane paint with high adhesion, high hardness, scratch resistance and waterproofness. It is divided into three types: mercerized, eggshell and matte. It has rich colors and supports computer color matching. For roller coating construction, it is recommended to use high-performance curing agent first.

The main paint components are water, quartz sand, additives and polyurethane silicone modified coatings. Component B is a nano-associative agent. The best paint film performance is achieved after 7 days of mixing A and B. The performance exceeds most international water-based industrial paint standards.

Compositon:

The main paint components are water, quartz sand, additives and polyurethane silicone modified coatings. Component B is a nano-associative agent. The best paint film performance is achieved after 7 days of mixing A and B. The performance exceeds most international water-based industrial paint standards.

Performance:

High hardness: provide high -hardness and excellent resistance.

High flexibility:Has high flexibility, and tensile stretching performance.

High adhesion: It has a strong adhesion, suitable for various materials such as ceramics, metals, wood, glass,JRC resin and other materials.

Strong waterproofing: superior waterproof performance, suitable for humid environment and soaking places in all year round.

Strong alkaline: suitable for strong alkaline materials such as cement floor.

Color persistence:protect the stability of color pulp, make color saturation and durability higher.

Time tolerance: persistent weather resistance, 10 years of outdoor project warranty (non -artificial damage).

Fire fire level: in water -based coatings, the fire level is very high(Except for professional fireproof coatings).

Antibacteriality:anti -mildew, anti -bacterial, providing additional dry membrane anti -mold guarantee.

High temperature resistance: under the condition of boiling water, keep the painting of the paint the basic performance unchanged.

Color Grading Index:

The main paint of component A can be tinted and is divided into three chromaticity base paints: light base L, medium base M and dark base D. The color code of the color-changing paint is: OST-XX-0000X. The first letter X in the middle represents the color-changing series, the second X represents the glossiness (L represents gloss, Y represents matte), the following 4 digits represent the color-changing number, and the last letter X represents the type of color-changing base paint (L represents light base, M represents medium base). When using, after the A base paint is tinted, add the nano-associative agent of component B, mix well, and then it can be used. The standard mixing ratio of component A and component B is 7:1.

Do not use A and B for more than 3 hours after mixing.

For coloring, please use internationally renowned water-based environmentally friendly colorants or OURSTUCCO American-made colorants. You can ask the company for professional color cards and coloring data sheets, and do manual DIY coloring. The company provides gold-medal agents with DATACOLOR color picking system and fully automatic computer coloring system. After formal training, they can experience color and provide services.

Color card color code for professional color-changing paint: Adopting the 1011 color coding system of artistic paint, taking into account two major types of agents who use manual color matching and fully automatic computer color matching, providing conventional light base (L) and medium base (M) color matching. For darker colors, please use dark base (D) color matching, please consult the American OURSTUCCO company for details.

Standard Construction Process:

1. Clean up grass -roots materials: Clean the surface of (including glass, ceramics, metals, wood, stone, GRC Resin, cement floor, epoxy floor, etc.) and dry them.

2. Mixed AB component: Mix the specific coatings A component A and the B component at 6: 1, and mix it evenly. (After mixing A and B, it is recommended to use it within 3 hours)

3. Apply brush for the first time (dry 6 hours or more)

4 .Pick up the second time (you can use it slightly after 24 hours, and reach the best performance after 7 days)

Supplementary description:

Aluminum gusset color change coating: need to apply aluminum substrate professional primer

Cement floor and self -flowing: need to paint the professional primer of cement.

Technical Data:

Coverage: Indoor speciality coatings. Approximately 1 litre per 5~8 square meters on smooth surface; speciality coatings for exterior use approximately 1 liter per 4.5~7square meters; Glass paint approximately 1 liter per 10~15 square meters; Metal paint approximately 1 liter per 5~8 square meters; Ceramic coatings approximately 1 liter per 5~8 square meters; Wood paint approximately 1 liter per 4.5~8 square meters; Cement floor coatings approximately 1 liter per 4~8 square meters.

Environmental protection:

OURSTUCCO integrates the concept of environmental protection into the entire product series. The product has a very low -industry VOC organic volatile object and known as a variety of substances that are harmful to human health.

All the production materials of the company are selected from well -known suppliers from professional fields around the world. The products have paid attention to environmental protection and health from the source, and have become sustainable coatings. The company has won many international environmental certifications.

LIMITED LIFETIME WARRANTY:If this coating does not perform as specified above, Ourstucco.Inc will, at its option, upon receipt of proof of purchase, either provide you with an equal amount of new coating or refund the purchase price of this coating. This warranty does not cover any claims, whether based on breach of express or implied warranty, negligence, strict liability or any other legal theory.

To request a material safety data sheet or to consult with an ourstucco certified coatings expert, please drop us a line at angel@ourstucco.com.

POPULAR COLORS

Testimonials

-

The colors are very pretty The refreshed doors go very well with the style of the home Like getting a new home !

Lisa

-

The surface of the refurbished tiles is wear-resistant and scratch-resistant and l never thought refurbishment would become so easy

Jennie

-

Very environmentally friendly, the product has no particular smell and makes us feel very safe and secure

Ellen

-

The quality of the product is very good the construction is very easy and the surface is very strong The multi-layerec texture and very plain color is the style of wall l wanted

Jeff